The InBrick system combines the lasting beauty and durability of traditional brick with all the benefits and efficiencies of precast concrete. InBrick is considerably faster than traditional brickwork, allowing quick enclosure and removing the brick façade from the critical path. InBrick is prefabricated offsite to allow faster construction times onsite - saving time and money.

InBrick is available in multiple brick sizes; Australian, European, UK, US, and is customisable to suit your project.

With limitless options when it comes to the range of brick tiles on offer and the ways in which they can be applied, InBrick enables the creation of truly original buildings.

InBrick means greater design flexibility. InBrick provides a structural design solution using conventional precast methods that accommodates arches, headers, soffits, and multiple coursing patterns and brick sizes. The range of colours, sizes and textures on offer, from traditional brick finishes to precision look glazed options, is limitless … meaning anything is possible.

For architects

InBrick provides a structural design solution using conventional precast methods of installation and doesn’t require additional labour on site, or post installation surface treatment. Using InBrick means accelerated construction and enclosure times, resulting in considerable cost efficiencies. Fabricated offsite and ready to install, InBrick accommodates any brick shape or size and can be used on a variety of project applications – pre-cast, tilt-up or cast in place. And because it has a genuine brick finish, InBrick is very low maintenance.

For developers

and builders

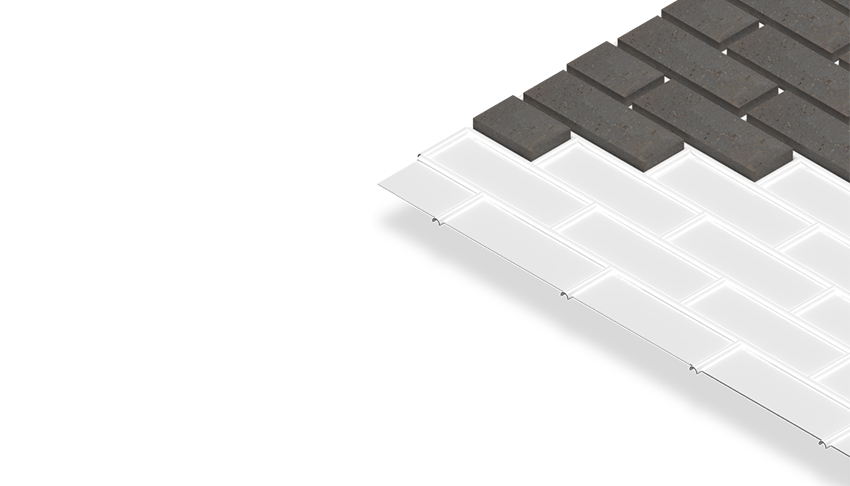

InBrick provides a tried and tested system from the USA that reduces labour time and is easy to handle and assemble, unlike anything else on the market. InBrick can be assembled on any bed, without the need for a subfloor or specialised forms. The single use design means no wash-down is required between cycles and no dedicated brick bed allocation.

InBrick can accommodate any brick shape or size and is supported by a range of accessories designed to make assembly easier and faster. It can be used for a variety of project applications – pre-cast, tilt-up or cast in place and is ideal for repeat panels.

For precast

contractors

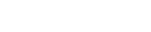

PATENTED SINGLE LINER TECHNOLOGY

The InBrick system uses VersaLiner®, a patented single liner technology, to embed thin brick tiles into precast concrete. It is a patented, single-use liner that offers a multitude of advantages, including:

- Higher production efficiencies

- Faster construction

- Lower labour cost

- Quicker clean up

- Better overall finish

- Faster cycle times

- More realistic mortar joints

- Multiple brick sizing

- Greater design flexibility

WHAT IS INBRICK?

The InBrick System.

A quick and

creative solution.

- Achieves a real brick look and feel

- Design flexibility with limitless range of brick colours and textures to choose from

- Accommodates arches, headers, soffits and multiple coursing patterns and brick sizes

- Combines the aesthetic of brick with the benefits of offsite manufacture

- Cost-effective way of achieving intricate brick detailing

- Structurally sound and durable - precast concrete panels are strong and resistant to impact

- Excellent fire-resistance and acoustic properties

- The bond of brick tiles and concrete is permanent

- Easy to install with accelerated construction and enclosure times

- Prefabricated offsite and delivered ready to install

- Ideal solution where access is restricted or project schedule demands fast onsite construction

- Speeds up the construction process, reducing construction costs

- Can be used in a variety of project applications: pre-cast, tilt-up or cast in place

- Ideal for repeat panels

- Low maintenance

- Independent NATA Testing for mechanical embedment strength – exceeding 1Mpa of extraction force

- Extensive design and technical support from PGH Bricks & Pavers - one of Australia’s largest brick manufacturers

- Backed by CSR

InBrick features and

benefits